- The value of Trust

- Midni Respect and deliver the value of trust and Contribution to everyone's clean and green life.

Product

Dual Stage Auto Backwashing Filter

- Home

- >

- Product

- >

- Dual Stage Auto Backwashing Filter

Daul Stage Auto Backwashing Filter

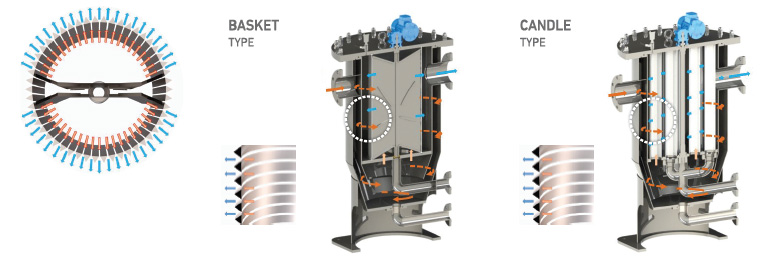

Dual stage auto backwashing filter is specially designed to improve the filtration efficiency and to prevent damage of the filter element and semi-permanent operation. Large particle is filtered through 1st filtration by centrifugal force and small particles are filtered through 2nd filtration with wedge wire screen. The automatic back-flushing operation by inlet/oulet differential pressure sensor and unique design with operational solution make a significant contribution to operational reliability and reduce operating and maintenance costs.

-

1

CHAMBER

-

2

GEARED MOTOR

-

3

CONTROL PANEL

-

4

DIFFERENTIAL PRESSURE SENSOR

-

5

BACKFLUSING VALVE

-

6

CHAMBER WASHING VALVE

-

7

SIGHT GLASS

-

8

AIR VENT

-

9

PRESSURE GAUGE

Feature

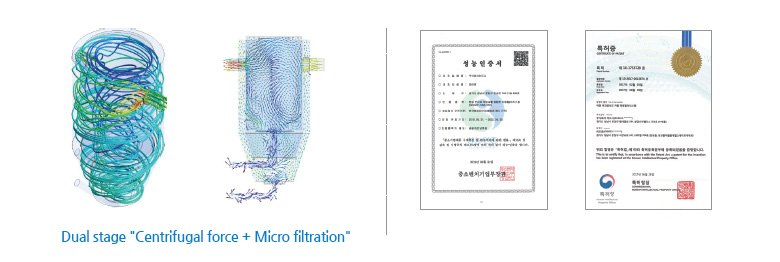

- Dual stage auto backwashing system (patented)

- Improved filtration efficiency by centrifugal force

- Optimised flow dynamic analysis

- No shutdown for auto backwash cycles

- Automatic backwashing filtration by differential pressure

- Wedge Wire Screen (>50um)

- WNo additional backwash pump

- Visually inspection by sight glass

Model

| Type | Model No | Flow(㎥/h) | Sizing | In/Out | Power |

|---|---|---|---|---|---|

| Basket | MDABF_50M_020 | 20 | 600S × 600W × 1150H | 65A | 0.75kw ~1.5kw |

| MDABF_50M_030 | 30 | 720S × 700W × 1250H | 80A | ||

| MDABF_50M_050 | 50 | 720S × 700W × 1350H | 100A | ||

| MDABF_50M_100 | 100 | 950S × 1100W × 1600H | 125A | ||

| MDABF_50M_150 | 150 | 1050S × 1150W × 1800H | 150A | ||

| MDABF_50M_200 | 200 | 1100S × 1250W × 2100H | 200A | ||

| Candle | MDABF_50M_200 | 200 | 950S × 1000W × 1900H | 200A | |

| MDABF_50M_300 | 300 | 1050S × 1150W × 1800H | 250A | ||

| MDABF_50M_400 | 400 | 1050S × 1100W × 1900H | 250A | ||

| MDABF_50M_500 | 500 | 1100S × 1150W × 2100H | 300A |

Filtration

Contamination particles are deposited at the bottom of the filter housing by centrifugal force. Small particles which passed through the 1st filtration are fi Itered through the micro filter element(50, 100um)

- 1st Filtration : Contamination particles are deposited at the bottom of the filter housing by centrifugal force.

- 2nd Filtration : Small particles which passed through the 1st filtration are filtered through wedge wire screen.(50,100um)

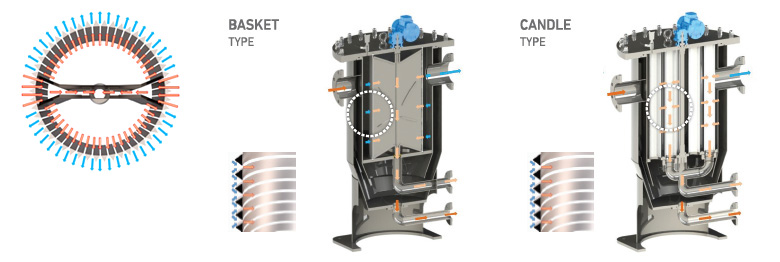

Backwashing

As the level of contamination increases, the differential pressure between inlet/outlet increases to the pre-set trigger point, backflushing starts automatically.

- 1st Filtration : When the differential pressure reaches the pre-set trigger point, backflushing starts automatically and particles are discharged to the outside. Sediment can be visually checked and manually discharged when needed

- 2nd Filtration : As the level of contamination increases and reaches the pre-set trigger point, the motor operates automatically and rotates the internal backwash devke. The contamination partkles are flushed to the outside.

Optimised Flow Dynamic Analysis